Alternator Easy Way Place 47uf Cap on Alternator Output and Ground

A popular form of performance upgrade revolves around applying electric current technology to older machines. While everybody else focuses on four-digit-horsepower LS engines with giant turbos or superchargers, permit's keep our goals far more than street-worthy and practical.

Among the nigh overlooked aspects of swapping belatedly-model engines into early Chevys is upgrading the charging system. Information technology was in the early '60s when alternators replaced generators. Since then, a landslide of charging system and alternator enhancements have followed. Nosotros decided we needed to focus our attention on some of the more than popular alternator conversions and wiring harness modifications necessary to conform them. We wanted to get input from a few professionals in the world of automotive charging, so we reached out to Tuff Stuff Performance and Painless Functioning.

On the back of GM alternators, you will find a 2- or four-wire plug forth with a large output stud. The large stud is for the output wire connectedness that is continued to the battery positive post.

Variations On Charging

There are at least a dozen or more than variations within the family tree of GM alternators, merely we'll condense them down to an essential four. The best style to upgrade the charging system on a '60s or '70s Chevy is to step-up to the latest model versions like the CS130D. Fifty-fifty a stock replacement CS130D volition offer more power at low speeds than previous models. That'due south just ane idea. Other alternatives that also work well.

Before we become into the bandy details, it's beneficial to investigate charging-output numbers. In nearly all cases, alternators are rated by maximum potential-amperage output. This is not amperage delivered while at idle! Based on multiple factors — like alternator design and pulley ratios — an alternator'southward output at idle can be far less than its maximum rating. The original 10-DN externally regulated alternator is probably not capable of much more than than 35 amps at idle. Back in the days of AM radios, that was enough to maintain organisation voltage.

Nosotros spoke with Mike Stasko, marketing manager for Tuff Stuff Performance, and he has a recommendation. "Once you determine the amp requirements of your vehicle, check to see if there is a higher amp alternator in the same alternator series. Information technology's always easier to bandy out a low-amp alternator with a high-amp unit as compared to adopting a different-series alternator."

Not All Alternators Are Created Equal

Tardily-model alternators are far more efficient at idle, so a stock 100-amp alternator might exist capable of 60 to 65 amps at idle. Simply let's look a little closer. Alternator rating numbers are generally tested with the alternator at ambience temperature. Unfortunately, with the charging system at normal operating temperature, internal resistance increases with oestrus, and the output drops, typically by 15 to 20 percent.

If you have an alternator rated at 100 amp at idle, its normal operating temperature is probably capable of only around 75 to 80 amps. That's something to think about if your twin electric fans and other electrical devices combine to pull more than seventy amps. The net result is a loss of organisation voltage at idle.

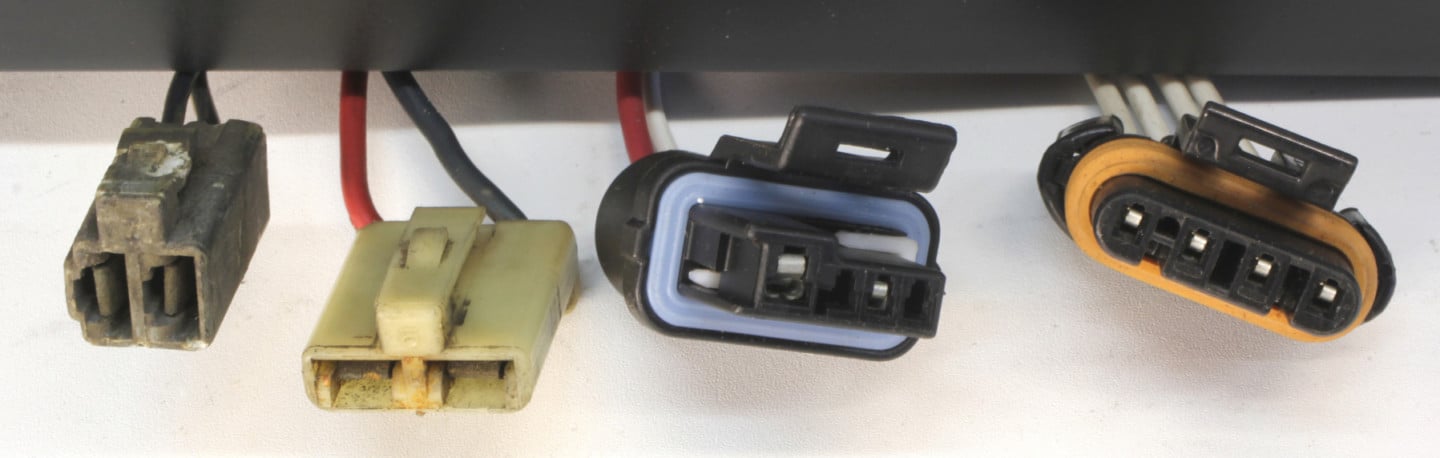

These are the four almost common alternator connectors. If you are non sure which alternator y'all have, the connector shape is a skilful indicator of alternator configuration. From left-to-correct: 10DN, ten/12SI, CS130/CS144, and CS-130D.

"If changing to a different alternator series, make certain the belt(s) line up and the wiring is in good condition," Mike states. "An alternator with a higher amp output than stock requires a heavier charge wire (the wire that connects the alternator to the battery) considering of the increased amperage."

To evaluate your charging system, try this simple experiment. With the engine idling at operating temperature, turn on all the electrical components such every bit the headlights, blower motor at total speed, 4-way flashers, electric fans, and the stereo at a reasonable level. Then, annotation the electrical arrangement operating voltage. If the voltmeter reads below 13 volts, none of the electrical devices — including the cooling fans — are running at tiptop efficiency. They demand a minimum of 13.5 volts.

All About The Connections

Assuming you want to upgrade, nosotros'll take a couple of the more common options and run through the wiring variables. The original 1960's GM alternator employs an external voltage regulator. This alternator (10-DN), uses a flat, ii-prong connexion at the back of the alternator. The other principal connection on the alternator is the output terminal that charges the bombardment.

The least expensive upgrade from the x-DN would be to step up to a 10-SI or 12-SI. The principal advantage of either unit is they utilize an internal voltage regulator (SI stands for organisation integrated). Only this is not a simple bolt-on conversion. The 10- and 12-SI units utilize a dissimilar ii-wire connector plug on the rear of the alternator. The Number 1 wire on the ten- or 12-SI is connected to the accuse alarm light on the nuance. The Number 2 wire is what is called the voltage sensing wire.

When converting from an external voltage regulator to an internal such as the 12-SI, many enthusiasts merely connect the Number ii voltage sensing wire directly to the output terminal. While this shortcut is simple and functional, it will not optimize the charging system. The voltage-sensing wire is all-time connected closer to the battery.

High-output alternators (greater than 100 amp) need a minimum of an 8-or-larger judge charge wire to reduce resistance. The bottom wire is AWG 12, the centre is AWG 10, and the largest is AWG vi. The largest is always improve (although clunky in appearance) for minimal resistance for alternators putting out more 100 amps.

Here's why using a remote voltage-sensing connection is a wise move. The main accuse wire on the back of the alternator is somewhen tied into the positive post on the battery. Nevertheless, this connection is oftentimes a long wire. This cable length creates resistance that can be easily measured with a uncomplicated charging organization efficiency test.

With the engine at idle — and several components like headlights, electric cooling fans, and perhaps the heater fan, operating, compare the voltage readings at the alternator to those at the battery. There will generally be a slight voltage driblet at the bombardment of around 0.l to 0.lx volt. By locating the voltage-sensing wire closer to the battery, the alternator tin can compensate for this slight drib in voltage and maintain the overall electric system at effectually 14 volts. With the voltage-sensing wire connected to the output concluding, this half-volt drop is non measured and the entire charging organisation nether-performs.

Singled Out

This is also a good place to mention one-wire alternators. These aftermarket alternators eliminate the warning light and voltage-sensing wire connections all OE alternators use. Voltage sensing is accomplished internally, which (equally nosotros just covered) is one reason why ane-wire alternators are not equally efficient every bit a remote-sensing alternator.

Another minor disadvantage to ane-wire alternators is the rotor in the alternator must reach a certain speed to self-excite. This usually requires the driver to rev the engine to increase internal voltage to sufficiently excite the alternator to begin charging. This isn't a huge issue. Simply, you need to be enlightened of this and rev the engine after it starts to ensure the charging system is functioning. Remote-sensing alternators are capable of charging the moment the engine starts.

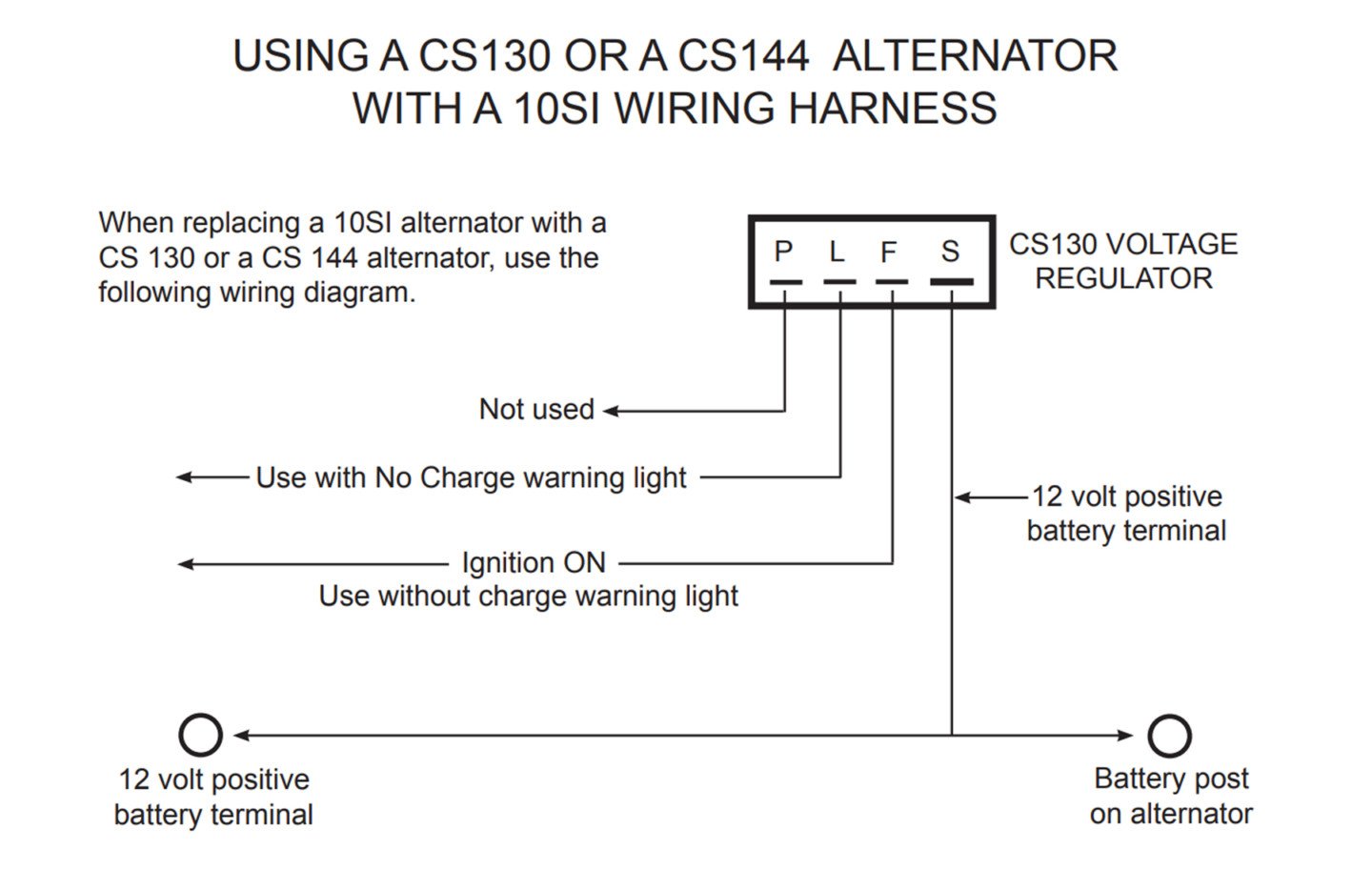

This is a Tuff Stuff illustration of how to convert a typical mid-'60s 10DN alternator to a much more robust CS-130. Tuff Stuff also sells a plug-in harness that volition accomplish this based on whether the automobile has a warning lite or not.

Among the available charging-system alternatives, yous tin choose to just upgrade to a college output alternator within the same pattern as your existing alternator, or update with a after model unit of measurement with more output. The simplest would be to upgrade your current alternator. For example, Tuff Stuff Functioning offers a higher output 10-DN option. Retaining a 10-DN with the separate voltage regulator might be a good thought for those who desire to retain the original appearance — for restoration purposes. If that's not of import, it's usually better to increase output and efficiency past stepping up to a newer model alternator like a CS-130 or larger CS-144.

Some Resistance Required

Let's become through an example of upgrading a '67 Chevelle with a 383ci pocket-sized-cake that has been converted to a CS-130 alternator. The auto retains the original mill x-DN external-regulator wiring. M&H Wire Fabricators tin build a plug-in-replacement forward-lamp harness that integrates with the new alternator by just plugging it in. This is the cleanest style to upgrade. As a less expensive culling, Painless Wiring offers a replacement CS-130 pigtail connector that tin easily exist spliced into place.

A common charging system effect with older cars is excessive resistance between the alternator and the bombardment. A quick test with the engine idling is to turn on several electric accessories similar headlights and the heater fan. Then, test voltage at the rear of the alternator and compare that to the voltage at the battery. If the voltage at the battery is within 0.five-volt of the alternator voltage, then the accuse wire is okay. If it drops more than 0.06-volt — like hither at 13.97 volts — the charge wire is too modest, or there is resistance at the connections.

All late-model alternators use an electronic voltage regulator. If your car is like this Chevelle and has a voltmeter or factory ammeter gauge without a charging system alert light, a resistor must be wired into the warning calorie-free excursion. Essentially, the resistor takes the place of the load created by the warning light.

We were curious as to why this resistor is important, and according to Painless engineer Eric Cowden, "The resistor limits the amperage the exciter wire can supply. In factory applications, either a charge-indicator lite or ECM provides this one amp or less, switched 12-volt source. Without this resistance, too much amperage reaches the regulator and causes information technology to burn upwards."

This Painless Performance analogy shows how the CS-130 and CS-144 alternators should be wired. The "S" connection on the alternator (left image) is the larger pivot on the far left while the "L" is second from the correct. Note the cartoon shows the external shape of the connector as rounded on i terminate while the internal shape is rectangular.

Cowden added this further explanation, "if you take watts divided by volts, you get amps. So, with this resistor, under normal charging circumstances, y'all are never putting more than than 0.v amp to the alternator." Here's the math that backs that up:

v watts / xiv volts = 0.35 amps

Of grade, but wiring the Painless connector to a alarm light accomplishes the same affair every bit the resistor, so i or the other is all that is needed. This is true for all afterward model alternators with internal voltage regulators and is why Painless includes the resistor in every pigtail conversion.

We make this point because it is possible to buy a replacement alternator pigtail from almost whatever auto parts store. These are ofttimes less expensive, just not packaged with a resistor. If y'all are using a standard pigtail (perhaps pulled from a junkyard vehicle), you lot demand to know which wire is the voltage-sensing wire and which one is the exciter wire that needs either a charge-indicator light or a resistor.

We've used these two-post concluding blocks, available from Jegs, for mounting both alive bombardment power and switched power. This makes an excellent spot for the voltage-sensing wire connection when this terminal block is mounted near the battery.

To keep this story brief, nosotros have not taken a deep dive into physically mounting these unlike alternators to diverse engines, as this can get somewhat complicated. To simplify this equally much as possible, the newer CS130 and CS144 alternators are a great option for Gen I minor- and big-block Chevys, while the CS-130D is commonly used on factory accompaniment drives for LS engines.

With this review of the wiring harness differences, updating your charging system should not exist very intimidating. Information technology's simple in one case you understand how the arrangement works.

Source: https://www.chevyhardcore.com/tech-stories/ignition-electronics-efi/alternator-upgrade-wiring-tips-for-popular-gm-charging-systems/

0 Response to "Alternator Easy Way Place 47uf Cap on Alternator Output and Ground"

Post a Comment